Statistical process control (SPC) is a method of quality control which uses statistical methods. SPC is applied in order to monitor and control a process. Monitoring and controlling the process ensures that it operates at its full potential. At its full potential, the process can make as much conforming product as possible with a minimum (if not an elimination) of waste (rework or trash). SPC can be applied to any process where the "conforming product" (product meeting specifications) output can be measured.

The concepts of Statistical Process Control (SPC) were initially developed by Dr. Walter Shewhart of Bell Laboratories in the 1920's, and were expanded upon by Dr. W. Edwards Deming, who introduced SPC to Japanese industry after WWII. After early successful adoption by Japanese firms, Statistical Process Control has now been incorporated by organizations around the world as a primary tool to improve product quality by reducing process variation.

Implementing Statistical Process Control

Deploying Statistical Process Control is a process in itself, requiring organizational commitment across functional boundaries. The flow-chart below outlines the major components of an effective SPC effort. The process steps are numbered for reference.

1. Determine Measurement Method

Statistical Process Control is based on the analysis of data, so the first step is to decide what data to collect. There are two categories of control chart distinguished by the type of data used: Variable or Attribute.

Variable data comes from measurements on a

continuous scale, such as: temperature, time, distance, weight.

Attribute data is based on upon discrete distinctions such as good/bad,

percentage defective, or number defective per hundred.

2. & 3. Qualify the Measurement System

A critical but often overlooked step in the process is to qualify the measurement system. No measurement system is without measurement error. If that error exceeds an acceptable level, the data cannot be acted upon reliably. For example: a Midwest building products manufacturer found that many important measurements of its most critical processes had error in excess of 200% of the process tolerance. Using this erroneous data, the process was often adjusted in the wrong direction - adding to instability rather than reducing variability. See the Measurement Systems Analysis section of the Toolbox for additional help with this subject.4. & 5. Initiate Data Collection and SPC Charting

Develop a sampling plan to collect data (subgroups) in a random fashion at a determined frequency. Be sure to train the data collectors in proper measurement and charting techniques. Establish subgroups following a rational subgrouping strategy so that process variation is captured BETWEEN subgroups rather than WITHIN subgroups. If process variation (e.g. from two different shifts) is captured within one subgroup, the resulting control limits will be wider, and the chart will be insensitive to process shifts.The type of chart used will be dependent upon the type of data collected as well as the subgroup size, as shown by the table below. A bar, or line, above a letter denotes the average value for that subgroup. Likewise, a double bar denotes an average of averages.

Consider the example of two subgroups, each with 5 observations. The first subgroup's values are: 3,4,5,4,4 - yielding a subgroup average of 4 (x̄1). The second subgroup has the following values: 5,4,5,6,5 - yielding an average of 5 (x̄2). The average of the two subgroup averages is (4 + 5)/2 = 4.5, which is called X double-bar (̿x), because it is the average of the averages.

You can see examples of charts in Section 9 on Control Limits.

6. & 7. Develop and Document Reaction Plan

Each process charted should have a defined reaction plan to guide the actions to those using the chart in the event of an out-of-control or out-of-specification condition. Read Section 10 below to understand how to detect out-of-control conditions.One simple way to express the reaction plan is to create a flow chart with a reference number, and reference the flow chart on the SPC chart. Many reaction plans will be similar, or even identical for various processes. Following is an example of a reaction plan flow chart:

8. Add Chart to Control Plan

A control plan should be maintained that contains all pertinent information on each chart that is maintained, including:- Chart Type

- Chart Champion - Person(s) responsible to collect and chart the data

- Chart Location

- Measurement Method

- >Measurement System Analysis (Acceptable Error?)

- Reaction Plan

- Gauge Number - Tied in with calibration program

- Sampling Plan

- Process Stability Status

- Cp & Cpk

9. Calculate Control Limits After 20-25 Subgroups.

Terms used in the various control chart formulas are summarized by the table below:

(Here n = subgroup or sample size and k = number of subgroups or samples)

Values for formula constants are provided by the following charts:

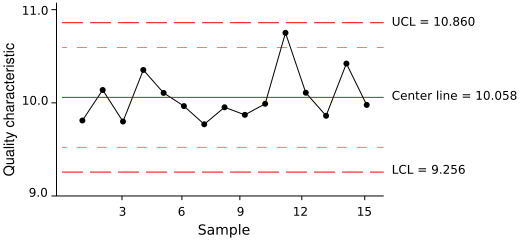

Chart examples:

X and R Chart

p-Chart

10. Assess Control.

After establishing control limits, the next step is to assess whether or not the process is in control (statistically stable over time). This determination is made by observing the plot point patterns and applying six simple rules to identify an out-of-control condition.Out of Control Conditions:

- If one or more points falls outside of the upper control limit (UCL), or lower control limit (LCL). The UCL and LCL are three standard deviations on either side of the mean - see section A of the illustration below.

- If two out of three successive points fall in the area that is beyond two standard deviations from the mean, either above or below - see section B of the illustration below.

- If four out of five successive points fall in the area that is beyond one standard deviation from the mean, either above or below - see section C of the illustration below.

- If there is a run of six or more points that are all either successively higher or successively lower - see section D of the illustration below.

- If eight or more points fall on either side of the mean (some organization use 7 points, some 9) - see section E of the illustration below.

- If 15 points in a row fall within the area on either side of the mean that is one standard deviation from the mean - see section F of the illustration below.

When corrective action is successful, make a note on the chart to explain what happened.

11. & 12. Analyze Data to Identify Root Cause and Correct

If an out-of-control condition is noted, the next step is to collect and analyze data to identify the root cause. Several tools are available through the MoreSteam.com Toolbox function to assist this effort - see the Toolbox Home Page. You can use MoreSteam.com's Traction® to manage projects using the Six Sigma DMAIC and DFSS processes.Remember to review old control charts for the process if they exist - there may be notes from earlier incidents that will illuminate the current condition.

13. Design and Implement Actions to Improve Process Capability

After identifying the root cause, you will want to design and implement actions to eliminate special causes and improve the stability of the process. You can use the Corrective Action Matrix to help organize and track the actions by identifying responsibilities and target dates.14. & 15. Calculate Cp and Cpk and Compare to Benchmark

The ability of a process to meet specifications (customer expectations) is defined as Process Capability, which is measured by indexes that compare the spread (variability) and centering of the process to the upper and lower specifications. The difference between the upper and lower specification is know as the tolerance.

After establishing stability - a process in

control - the process can be compared to the tolerance to see how much

of the process falls inside or outside of the specifications. Note: this

analysis requires that the process be normally distributed.

Distributions with other shapes are beyond the scope of this material.

The first step is to compare the natural six-sigma spread of the process to the tolerance. This index is known as Cp.

Here is the information you will need to calculate the Cp and Cpk:- Process average, or x̄

- Upper Specification Limit (USL) and Lower Specification Limit (LSL).

- The Process Standard Deviation ( σest). This can be calculated directly from the individual data, or can be estimated by: σest = R̄ / d2

The Lower Specification Limit is 48

The Nominal, or Target Specification is 55

The Upper Specification Limit is 60

Therefore, the Tolerance is 60 - 48, or 12

As seen in the illustration, the 6-Sigma process spread is 9.

Therefore, the Cp is 12/9 or 1.33.

The Nominal, or Target Specification is 55

The Upper Specification Limit is 60

Therefore, the Tolerance is 60 - 48, or 12

As seen in the illustration, the 6-Sigma process spread is 9.

Therefore, the Cp is 12/9 or 1.33.

The next step is to calculate the Cpk index:

So Cpk is 0.67, indicating that a small percentage of the process output is defective (about 2.3%). Without reducing variability, the Cpk could be improved to a maximum1.33, the Cp value, by centering the process. Further improvements beyond that level will require actions to reduce process variability.

16. Monitor and Focus Efforts on Next Highest Priority

The last step in the process is to continue to monitor the process and move on to the next highest priority.