Techniques of Material Control

Material is main current asset of business which is needed for finished product. It also has big proportion in total cost. These two points attract businessman to control the material, so that supply of stock should be continue without any delay and also it should be at optimum level without any over-stocking problem. For this, cost accountant has to use following techniques for controlling the material or inventory.

1st Technique : Setting of various stock level

In this technique of material control, we study and control by calculating different level of quantity of stock. With our past records, we have the data of normal usage, maximum usage, minimum usages, re-order quantity and minimum and maximum period and its mid will be average period. With this data, we can find following stock level

a) Re-ordering level

It is the level of stock quantity between minimum and maximum level and material order was sent for getting fresh stock.

formula

maximum usage of stock X maximum delivery period

b) Minimum level

It is the minimum balance, which must be maintained in hand at all times, so that there is no stoppage of production due to non availability of inventory.

Remember

You must need re-order level for getting it.

Formula

Re-order level - ( Normal usage X average period )

c) Maximum level

It shows maximum quantity which should be in the stock, if we buy more, it means we are wasting money.

formula

re-order level X re-order quantity - ( minimum usage X minimum period )

d) Average Stock Level

This is the average of minimum and maximum level and it can be calculated by adding minimum level and maximum level and divided by 2.

formula

minimum level + maximum level / 2

e) Danger level

It is the level at which normal issues of the raw material inventory are stopped and emergency issues are only made.

2.ABC Analysis ( Technique of Material Control)

ABC analysis is that technique of material control in which we divide our material into three categories and investment

is done according to the value and nature of that category’s materials.

After this, we control of material according to their level of

investment. We need not to control all the categories but we have to

control those materials which are in a category.A category materials and its control

In these category materials, we include 10% of total material, but its cost will be high, so its investment requirement will also be very high and it may be 70% of total investment in inventory. Store keeper should make safe these materials from any wastage, because its price or demand is very high. Store keeper also keeps its economic order quantity and tries to decrease misuse of money in this category.

A category which will also require special attention due to the “large amount of money” they represent. A small “mistake” in managing the few A Category materials may cost a lot to your company.

B category materials and its control

In this category, there are many normal materials can be included which are needed for production. Store keeper can classify 20% of material and we need 20% of total investment in this type of inventory for buying. But its control is also necessary, because without this, production may be delay. So, store keeper should not ignore its control and for continuing supply, storekeeper should maintain its minimum, maximum and re-order level.

C category materials and its control

There is no need to control this type of material but normal care is needed for keeping this material in right position before using it for production. Its quantity is of 70% of total quantity but cost is 10% of total investment in inventory. So, overstocking can increase store cost and interest on capital. So, purchase should be in hand.

Again Remember

- The A segments represent approximately 70% of the total spend within a category - High attention

- The B segments represent the following 20% of the total spend within a category - Normal attention

- The C segments are the remaining (most of the time several segments) which Represents the final 10% of the total spend - Low attention

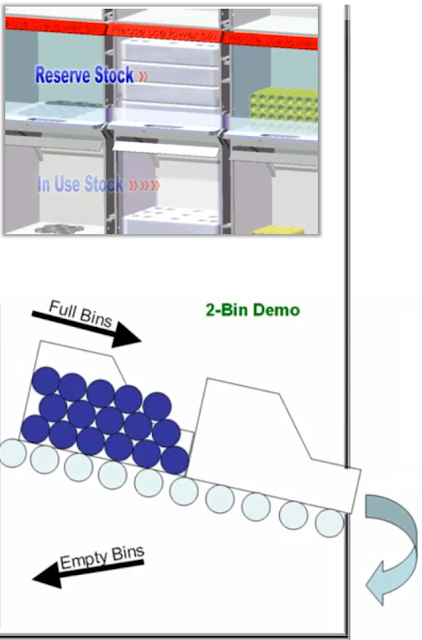

3.Two Bin System

Two bin system is used for the material control. It is that technique of material control in which we have two bins, one is used for in use minimum stock and second bin is used for reserve stock or to keep the remaining quantity of material. This system of inventory control is also called in USA kanban. First bin is utilized for issuing the material for production and then, second bin is used. Its record is done on bin cards and store ledger card.

How to two Bin System work?

Many companies make the layout of two bin according to requirement of customers. First of all, we use first bin and when it will be closed, next bin will automatically shift in first bin.

4.Continuous Stock Verification

Continuous stock verification is that technique of material control in which company appoints some experts who verifies all the stock physically with its record. It is just like internal audit of store. These experts are independent from store and they have right to check the material at any time without providing advance information to store staff. This surprise checking through continuous stock verification makes store staff more responsible for duty. There are also other benefits of continuous stock like it will make store keeper more sober and moral to do the duty. He knows that the store is also controlled by experts. He tries to best to reduce all inherent shortcomings.

Continuous stock verification will also helpful to remove all discrepancies between actual stock and book record of stock and expert can identify for this mistake and take action against him.

Steps in Setting Up an effective stock verification system

1. → To appoint technical expert personalities for this work, who have knowledge the measurement system of material of stock. For example, method of measuring cable will be different to measuring milk.

2. → Direction of surprise checking should be given by heads.

3. → Stock in transit should not be mixed in normal stock at the time of checking.

4. → To make stock verification sheet after actual verification of stock and in this sheet, experts should record the results of verification.

Results of Stock Verification

Following result can be found during stock verification.

1. Stock is less due to theft

2. Pilferage

3. natural losses

4. loss stock due to changing in temperature

5. errors in counting

6. loss due to careless handling and careless measurement

7. Any other losses may be the nature of unavoidable or avoidable